The Role of Scanning Electron Microscopy in the Automotive Industry

The automotive industry has always been at the forefront of technological advancement. Every year, new models are released that boast better safety features, more power, and improved fuel efficiency. However, these advancements are not possible without innovations in materials science and engineering. One tool that is invaluable in this regard is Scanning Electron Microscopy (SEM). This blog post will explore the role of scanning electron microscopy in the automotive industry and the benefits it provides.

What is Scanning Electron Microscopy?

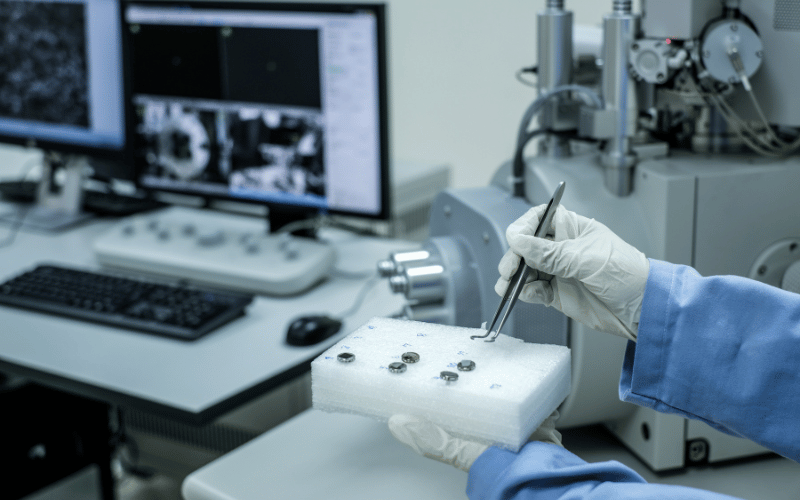

As a refresher, let us first define scanning electron microscopy.

It is a type of electron microscope that uses a focused beam of electrons to create high-resolution images of surfaces and materials. Unlike traditional optical microscopes, SEM can provide detailed information about a material’s morphology, structure, and composition. In the automotive industry, SEM can be used to analyze various materials such as metals, plastics, and composites.

Overview of the Roles of SEM in the Automotive Industry

An SEM is more than just a microscope; it’s a window into the microscopic world of automotive materials. Let’s take a look at some of the key roles of an SEM to have an idea of how it’s revolutionizing the automotive industry:

Quality Control and Failure Analysis

One of the primary uses of SEM in the automotive industry is for quality control and failure analysis. SEM can be used to identify defects and structural abnormalities that may affect a material’s mechanical properties. For example, SEM can be used to find cracks, porosity, and corrosion in metals and alloys. This information can then be used to determine the cause of failure and develop mitigation strategies.

Material Characterization

In addition to quality control and failure analysis, SEM can be used to characterize materials used in the automotive industry. SEM can help researchers understand the morphology of a material, such as its surface roughness, grain size, and crystal structure. This information is essential in designing materials with the desired mechanical, electrical, and thermal properties.

Analysis of Particulate Matter

With the increasing concern for air pollution and its impact on human health, there is a growing need to understand and analyze particulate matter emissions from vehicles. SEM can be used to analyze particulate matter collected from exhaust systems and filters.

By studying the morphology, size distribution, and chemical composition of the particles, SEM can provide insights into the sources and characteristics of the emissions. This information can then be used to develop more efficient catalytic converters, filters, and exhaust systems to reduce harmful vehicle emissions.

Advancements in Lightweight Materials

The automotive industry is continuously striving to develop lighter vehicles with improved fuel efficiency. Lightweight materials such as aluminum, magnesium, and composites are becoming increasingly popular due to their high strength-to-weight ratio. However, these materials have unique microstructures that require careful characterization to optimize their performance. SEM is one of the tools that can be used to study the microstructure of lightweight materials and optimize their properties.

Optimization of Coatings and Surface Treatments

Coatings and surface treatments are used extensively in the automotive industry to improve the corrosion resistance, wear resistance, and lubrication properties of materials. SEM can be used to study the morphology and composition of coatings and surface treatments to optimize their performance. For example, SEM can be used to study the thickness and adhesion of coatings, as well as their tribological properties.

Future Directions of the Role of SEM in the Automotive Industry

The use of SEM in the automotive industry is expected to grow in the coming years. Ongoing research is being conducted to develop new lightweight materials that can further improve fuel efficiency. At the same time, there is a push to create greener, more sustainable materials that can replace traditional petrochemical-based components. SEM will continue to play a critical role in material development, as well as quality control and failure analysis, particularly in identifying any cracks, defects, or structural abnormalities that may affect the performance and longevity of automotive parts.

Key Takeaways: Role of Scanning Electron Microscopy in the Automotive Industry

SEM isn’t just another tool — it’s a game-changer in the automotive industry. Imagine being able to zoom in and understand the tiniest details of a car’s material. That’s what SEM does. It’s like having a super-microscope that reveals secrets of materials that we couldn’t see before.

As the industry races towards a future of electric and self-driving cars, SEM will be more crucial than ever. It’s not just about building cars; it’s about pioneering the future of transportation.

Want to keep up with how SEM is driving the automotive industry forward? Subscribe to our blog for the latest insights and updates. Be a part of the journey where tiny particles make a huge impact!