The Role of SEM in the Medical Device Industry

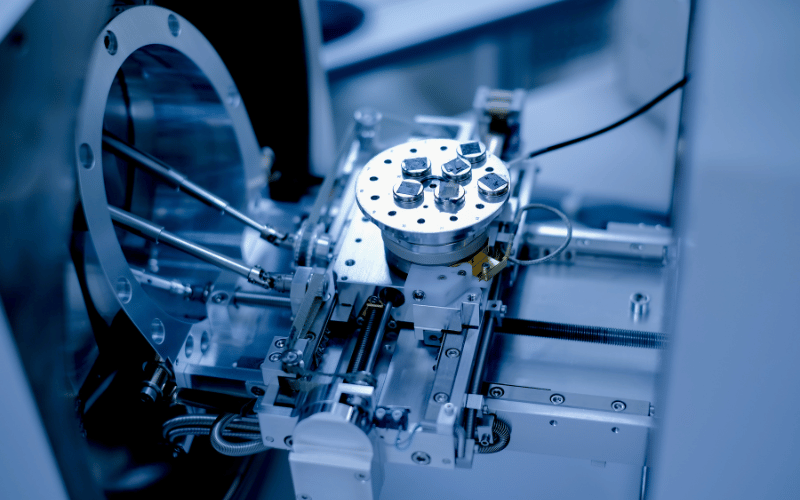

In the rapidly evolving landscape of healthcare technology, the role of SEM (Scanning Electron Microscopy) in the medical device industry has become increasingly pivotal. This sophisticated technology plays a critical role in enhancing the quality, safety, and functionality of medical devices.

In this blog, we’ll look into the multifaceted role of SEM in the medical device industry, highlighting its indispensable applications and the profound impact it has on the development and improvement of medical devices. Whether it’s through detailed material analysis or rigorous quality control, SEM stands as a cornerstone technology in the journey toward innovative and reliable medical solutions.

Sample Roles of SEM in the Medical Device Industry

The medical device industry is a field where precision and reliability are not just goals, but necessities. SEM plays a crucial role in achieving these standards. Let’s explore how SEM is used in various aspects of the medical device industry:

Surface Characterization

One of the primary uses of SEM in the medical device industry is for surface characterization. This involves examining the surface morphology, topography, and roughness of materials used in medical devices. SEM helps identify different materials and phases that are crucial for ensuring the safety and effectiveness of these devices. The use of both backscattered electron detector (BSD) and secondary electron detector (SED) in SEM provides comprehensive information about the surface of medical devices, making them safer and more reliable.

Quality Control

In quality control, SEM is used to inspect the surfaces of medical devices before production release. This inspection ensures that devices are defect-free and meet stringent specifications. Automated SEMs play a crucial role in maintaining high manufacturing standards and adhering to strict regulations.

Research and Development

SEM aids significantly in the research and development of new medical devices. It provides detailed visualizations of device components at the micro- and nanoscale. This insight is crucial throughout the development cycle, from selecting materials to scaling up production processes.

Failure Analysis

Failure analysis is a critical application of SEM, especially when an implantable medical device malfunctions. SEM allows manufacturers to investigate the root causes of device failures by revealing structural defects, fractures, and wear patterns. This non-destructive technique is vital in improving product reliability and ensuring patient safety.

Material Composition Analysis

The analysis of material composition is another essential application of SEM in this industry. Coupling SEM with Energy-Dispersive X-ray Spectroscopy (EDS) helps in assessing the elemental composition of materials. This is crucial for detecting contaminants and ensuring that the devices are composed of the intended materials, thus maintaining their integrity and functionality.

Microstructure Analysis

SEM is also employed for microstructure analysis of medical devices. These devices often have intricate microstructures that directly impact their properties and performance. High-resolution images provided by SEM are invaluable for understanding how materials interact with the human body, aiding in the design of devices with better biocompatibility.

Coating Evaluation

Many medical devices are coated with specialized materials. SEM is excellent for assessing the composition, thickness, and uniformity of these coatings. Techniques like ion milling prepare samples for precise characterization, ensuring that the coatings meet the necessary specifications for functionality and biocompatibility.

Regulatory Compliance

Finally, SEM is vital for regulatory compliance in the medical industry. Regulatory agencies often require thorough characterization and testing of medical devices. SEM provides the necessary visual evidence and data to demonstrate compliance with safety and quality standards.

Key Takeaways: Role of SEM in the Medical Device Industry

The role of SEM in the medical device industry is undeniably crucial. Its diverse applications, from surface characterization to regulatory compliance, underscore its significance in enhancing the safety, efficacy, and innovation of medical devices. As we’ve explored, SEM’s capabilities extend far beyond basic imaging; it is a tool that drives quality, reliability, and advancement in the medical field.

If you’re intrigued by the impact of SEM in medical technology and want to stay informed about the latest developments and insights in this dynamic field, don’t miss out on our upcoming content. Subscribe to our blog for regular updates on the world of electron microscopy. Stay ahead of the curve in understanding how cutting-edge tools like SEM are shaping the future of healthcare.