Linear Accelerator

LINASEC®: Advanced Linear Accelerator Technology for Security and NDT Applications

Comprehensive Security Scanning Solutions

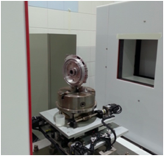

The LINASEC® Linear Accelerator System represents cutting-edge technology in non-destructive testing (NDT) and security scanning applications. This integrated system delivers powerful inspection capabilities for ports, borders, and industrial facilities requiring high-resolution imaging and material discrimination.

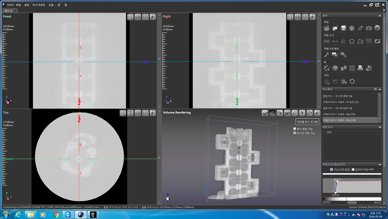

All-in-One System Integration

Core Components

- Linear accelerator unit

- RF generator

- High-frequency modulator

- High Voltage Power Supply (HVPS)

- Integrated radiation shielding

- Advanced power supply systems

- Comprehensive interface controls

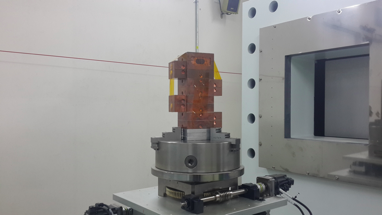

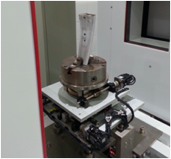

S-Band Accelerator Technology

Our S-band accelerator portfolio offers customizable solutions featuring:

- Variable dose rates

- Adjustable energy levels

- Customizable focal spot sizes

- Application-specific configurations

Dual Energy Capabilities Linear Accelerator

Advanced Material Discrimination

- Interlaced 6MeV and 9MeV acceleration

- Enhanced material identification

- Superior penetration capabilities

- Precise density analysis

Security Applications

- Cargo container inspection

- Vehicle screening

- Contraband detection

- Threat material identification

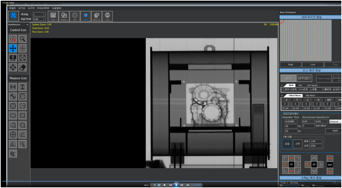

Industrial NDT Applications using Linear Accelerator

Quality Assurance

- Structural integrity verification

- Weld inspection

- Material composition analysis

- Internal defect detection

Benefits

- Non-destructive evaluation

- High-resolution imaging

- Real-time inspection

- Comprehensive data analysis

Technical Specifications

Performance Features

- Dual energy operation (6MeV/9MeV)

- Optimized beam characteristics

- Advanced scanning capabilities

- High throughput capacity

Integration Options

- Modular system design

- Flexible installation configurations

- Scalable solutions

- Custom interface options

Safety and Compliance

- Integrated radiation shielding

- International safety standards compliance

- Environmental protection features

- Operator safety protocols

Applications

Port and Border Security

- Container screening

- Vehicle inspection

- Customs verification

- Smuggling prevention

Industrial Testing

- Manufacturing quality control

- Infrastructure inspection

- Aerospace components

- Heavy industry applications

Specifications

LINASEC Series

| Description | Product Name | SM03 | SM06 | SM09 | SK15 |

|---|---|---|---|---|---|

| GENERATOR | Energy(Photon) Dose rate spot size Operating Frequency RF Power & Source RF Pulse Length Beam Pulse Length PRF (Pulse Repetition Frequency) Beam Flatness HVL(in) Radiographic Quality Range(mm) | 1/2/3 (MV) 0.25/2/3 (Gy/min-m) <2 mm (FWHM) 2998 ± 2 MHz(π/2-mode) 3.1MW (Magnetron) 1~5㎲ 1~3.5㎲ Up to 300Hz ≥72.5%@±7.5° 0.91 38~203 | 3.5/5/6 (MV) 2.5/5/8 (Gy/min-m) ≥62%@±7.5° 1.1 51~254 | 5/6/9 (MV) 6/10/30 (Gy/min-m) ≥55%@±7.5° 1.18 76~381 | 9/15 (MV) 50/140 (Gy/min-m) 5.5MW (klystron) 5㎲ 3.5㎲ ≥45%@±6° 1.25* 254~460 |

| POWER | Electrical Power Current TCU Pressure(Operating) TCU Temperature(Operating) | 380VAC 3Ø 50A/18A (TCU) 4~6 bar 15~40°C | |||

| ENVIRONMENT | Storage temperature Humidity Protection class(IP rating) Leakage(fraction) | 10~40°C 10~85% 66 1 x 10-3 |

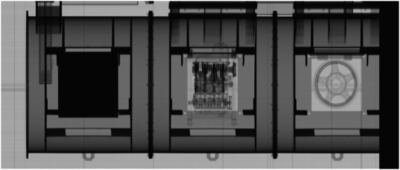

LINASEC CIS 9 & 6 (Cargo & Vehicle Inspection system)

| Description | Type | Electron Linear Accelerator |

|---|---|---|

| GENERAL SPECIFICATION | Nominal Energy Scanning Principle | 9 MeV(6 MeV) Container or Vehicle is transported via conveyor through X-ray Scanning system |

| SYSTEM SPECIFICATION | Inspection Throughput Minimum Crew Requirement Max. Dose Rate Spot Size Penetration(Steel) | 10 trucks / Hour (Maximum) 1 Image Operator, 1 System Operator & 1 Check in Operator 30.0Gy/min-m(8Gy/min-m) ≤2 mm 430mm(340mm) |

| DETECTOR SPECIFICATION | Type Photodiode Size Vertical Detector Pitch ADC Depth Penetration(Steel) Vertical Structure | Linear Diode Array 4 x30(mm) 4.6mm CdWO4 18bit Curved |

| IMAGE PROCESSING & HARDWARE | Image Analysis Data base workstation Hardware | Contrast & Edge enhancement, Filters, Marks, Annotations, Histogram Equalization, Review of Image, Image Conversion to standard format, Object measurement, Zoom & window images, Brightness & Contrast change, and etc SQL Database Dual-Core CPU at least 2.3 GHz, System memory at least 4 GB, Gigabit Ethernet Network Interface Card. |

| RADIATION PROTECTION SAFETY | Safety Area(WxL) Surveillance Regulations Dose in the environment | 20 x 38(m) Video Surveillance six color CCTV In compliance with WHO, ICRP 103 Less than 1 uSv/hour |

| HEALTH & SECURITY | Dose in the environment Dose rate in operator cabin | Less than 1 uSv/hour Less than 1 uSv/hour |

| BUILDING FEATURES | Building Parts Installation footprint Scanning height | Scanning building, Operators premises, Technical rooms & Spare parts storage room 20 x 38(m) 4.7m |

| OTHER | Education & Training | Technical training to be provided for 1 year(2 persons) by KAERI(Korea Atomic Energy Research Institute) |

Application