Revolutionary Metals Research: Laser Heated EBSD Analysis with Tabletop SEM

Laser Heated EBSD Experiments

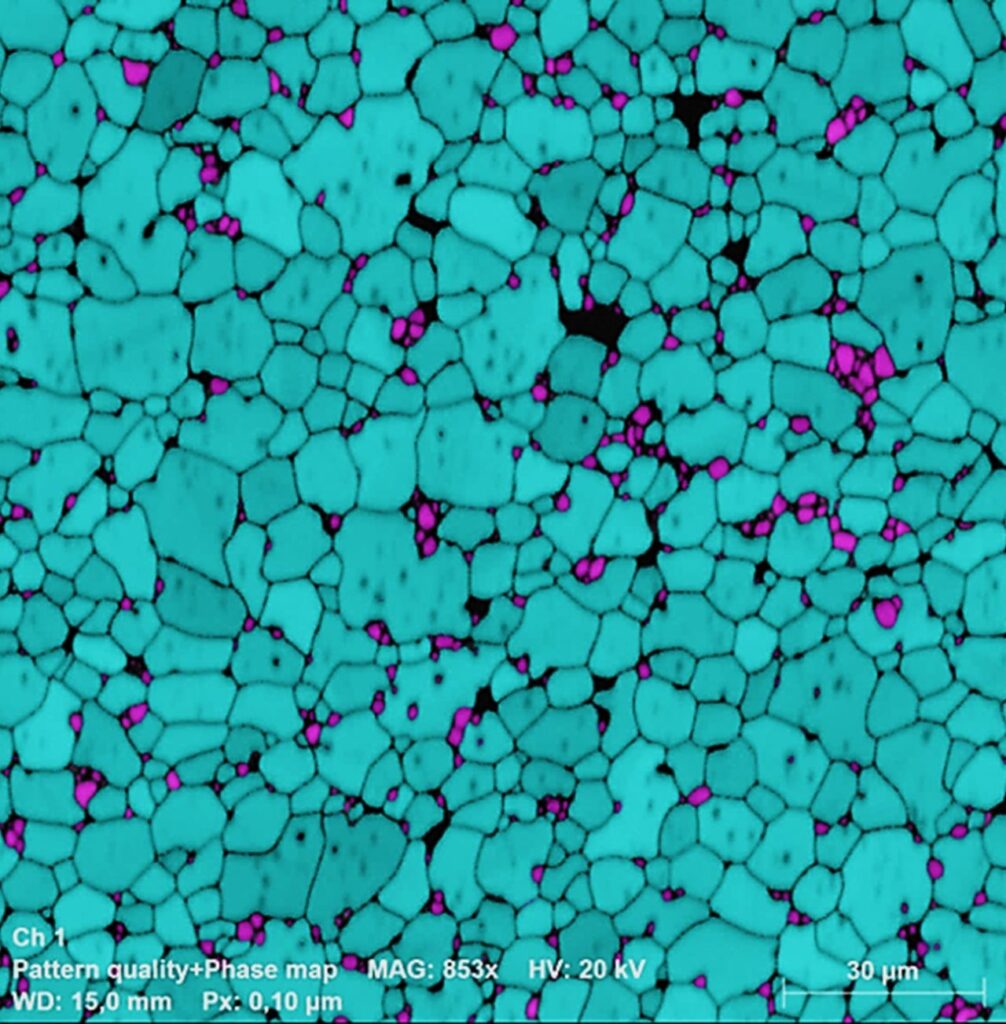

The integration of laser heating capabilities with Electron Backscatter Diffraction (EBSD) analysis represents a groundbreaking advancement in materials science research. When combined with the SNE-Alpha Tabletop Scanning Electron Microscope (SEM) equipped with Bruker EDXS capabilities, this innovative approach offers researchers unprecedented insights into material behavior under dynamic temperature conditions. In this comprehensive guide, we'll explore how this combination can transform your research capabilities while maintaining cost-effectiveness.

Understanding the Innovation: Laser Heating EBSD

The marriage of laser heating technology with EBSD analysis creates a powerful tool for studying material transformations in real-time. Traditional EBSD analysis provides crystallographic information about materials at room temperature, but adding laser heating capabilities opens up entirely new research possibilities. This combination allows researchers to observe and analyze phase transformations, recrystallization processes, and grain boundary evolution as they occur under controlled heating conditions.

Key Components of the System

The integrated system consists of several crucial elements:

- SNE-Alpha Tabletop SEM platform

- Bruker EDXS system (incorporating both EBSD and EDS capabilities)

- Precision-controlled laser heating module

- Advanced thermal monitoring systems

- Real-time data acquisition software

Advantages of Real-Time Laser Heating EBSD Analysis

1. Dynamic Observation of Phase Transformations

One of the most significant benefits of incorporating laser heating into EBSD analysis is the ability to observe phase transformations as they occur. This real-time capability offers several advantages:

- Direct observation of nucleation and growth processes

- Immediate feedback on transformation kinetics

- Ability to adjust experimental parameters on the fly

- Reduced risk of missing critical transformation events

2. Enhanced Temperature Control

The laser heating system provides precise temperature control with several benefits:

- Rapid heating and cooling rates

- Highly localized heating capabilities

- Minimal thermal drift

- Excellent temperature stability

- Reduced sample contamination compared to traditional heating stages

3. Improved Data Quality

Real-time analysis with laser heating offers superior data quality through:

- Minimal thermal gradient effects

- Reduced sample drift during heating

- Better signal-to-noise ratio

- More accurate phase identification

- Continuous data collection throughout thermal cycles

Applications in Materials Research

Metallurgical Studies

The system excels in various metallurgical applications:

- Phase transformation studies in steel and other alloys

- Recrystallization behavior analysis

- Grain boundary migration studies

- Precipitation sequence investigation

- Texture evolution monitoring

Advanced Materials Development

Researchers working on advanced materials benefit from:

- In-situ observation of shape memory alloys

- High-temperature superalloy behavior analysis

- Advanced ceramic material studies

- Novel composite material development

- Thin film behavior investigation

Cost-Effectiveness of Tabletop SEM Solutions

Economic Advantages

The SNE-Alpha Tabletop SEM offers significant cost benefits compared to full-size SEM systems:

- Initial Investment

- Lower purchase price

- Reduced installation costs

- Minimal facility modification requirements

- Smaller footprint reducing space costs

- Operating Costs

- Lower power consumption

- Reduced maintenance requirements

- Minimal specialized facility needs

- Lower cooling system requirements

- Training and Personnel

- Shorter learning curve

- Reduced operator training costs

- Less specialized knowledge required

- Greater accessibility for multiple users

Performance vs. Cost Analysis

While tabletop systems may have some limitations compared to full-size SEMs, the benefits often outweigh these constraints:

- Sufficient resolution for most applications

- Adequate working distance for laser integration

- Compatible with standard EBSD detectors

- Suitable for most common materials research

Real-Time Benefits for Research

Experimental Efficiency

Real-time analysis provides numerous advantages:

- Time Savings

- Immediate feedback on experimental parameters

- Reduced need for multiple sample preparations

- Faster iteration of research conditions

- More efficient use of research time

- Resource Optimization

- Reduced sample waste

- Lower energy consumption

- More efficient use of laboratory time

- Better utilization of research funds

Data Quality and Analysis

The real-time capabilities enhance data quality through:

- Continuous Monitoring

- Uninterrupted data collection

- Better statistical significance

- Improved trend identification

- More comprehensive phase transformation understanding

- Immediate Verification

- Quick validation of experimental parameters

- Rapid identification of experimental issues

- Immediate adjustment capabilities

- Better quality control

Implementation Considerations

Laboratory Setup

When implementing this system, consider:

- Space Requirements

- Compact footprint needed

- Minimal ventilation requirements

- Standard electrical supply sufficient

- Basic vibration isolation needed

- Integration Aspects

- Straightforward laser system integration

- Simple cooling system requirements

- Standard safety protocols

- Minimal additional infrastructure needed

Safety and Operation

Important safety considerations include:

- Laser Safety

- Class-appropriate safety measures

- Proper beam containment

- Operator training requirements

- Emergency shutdown procedures

- General Operation

- Standard SEM safety protocols

- Thermal management considerations

- Sample handling procedures

- Regular maintenance schedules

Future Perspectives of Laser Heated EBSD

Research Potential

The integration of laser heating with tabletop SEM-EBSD systems opens new research avenues:

- Advanced Materials Development

- Novel alloy development

- Smart materials research

- High-temperature materials studies

- Advanced coating development

- Process Optimization

- Manufacturing process improvement

- Heat treatment optimization

- Welding procedure development

- Surface modification studies

Technology Evolution

Expected developments include:

- System Improvements

- Enhanced temperature control

- Better spatial resolution

- Improved data processing

- Advanced automation capabilities

- Application Expansion

- New material classes

- Extended temperature ranges

- Novel experimental techniques

- Broader research applications

Conclusion

The integration of laser heating capabilities with the SNE-Alpha Tabletop SEM and Bruker EBSD system represents a significant advancement in materials research capabilities. This combination offers researchers a powerful, cost-effective tool for conducting sophisticated materials analysis with real-time temperature control. The system's ability to provide immediate feedback, coupled with its accessibility and efficiency, makes it an excellent choice for both academic and industrial research applications.

The cost benefits of using a tabletop system, combined with the advanced capabilities of laser heating and EBSD analysis, create a compelling package for materials research laboratories. As this technology continues to evolve, we can expect to see even more applications and capabilities emerge, further enhancing our understanding of material behavior under dynamic temperature conditions.

For researchers looking to maximize their research capabilities while maintaining budget consciousness, the combination of laser heating with tabletop SEM-EBSD analysis provides an optimal solution. This approach not only delivers high-quality scientific data but also offers the flexibility and efficiency needed in modern materials research.

https://www.nanoimages.com/tabletop-sem-products-scanning-electron-microscopes/bruker-edxs-ebsd-eds/