Semiconductors

Wafer inspection, defect analysis, process development, and quality control

The microelectronic devices we enjoy and depend on today would not be possible without electron microscopy. From R&D to production QC, scanning electron microscopy provides the resolution and analytical capabilities essential for semiconductor manufacturing and failure analysis.

The SNE-Alpha desktop SEM delivers the imaging performance needed for semiconductor applications in a compact, accessible format. With 5nm resolution, 1-30kV accelerating voltage range, and optional EDS integration, you can characterize devices with both high-resolution morphological imaging and elemental analysis.

Key Semiconductor Applications

- Wafer Inspection: Examine surface defects, contamination, and process variations across wafer surfaces

- Defect Analysis: Identify and characterize crystallographic defects, particles, and foreign materials

- Cross-Section Analysis: Measure layer thicknesses, via profiles, and interface quality

- Failure Analysis: Investigate device failures, electrical shorts, and manufacturing defects

- Process Development: Optimize etch profiles, deposition uniformity, and lithography patterns

- Particle Identification: Combine SEM imaging with EDS to identify contamination sources

Why Desktop SEM for Semiconductors?

While many semiconductor fabs rely on large floor-model SEMs, a desktop SEM like the SNE-Alpha offers significant advantages for certain applications:

- Fast Turnaround: 90-second pump-down means quick sample inspection without waiting for central lab availability

- Point-of-Use: Locate the SEM near your cleanroom or process line for immediate feedback

- R&D Flexibility: Ideal for university research, startups, and development labs

- Cost Effective: Lower capital and operating costs than floor-model alternatives

Semiconductor SEM Images

Sample images captured with the SNE-Alpha desktop SEM. Click to enlarge.

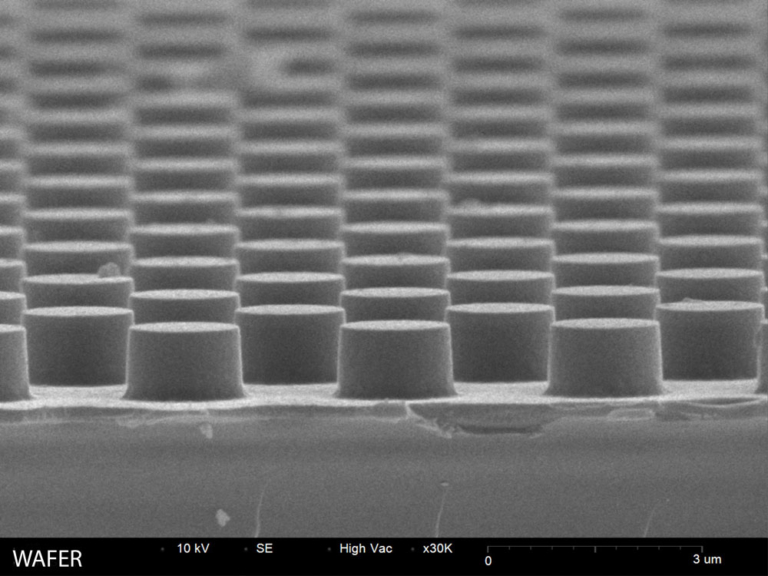

Silicon Wafer

Wafer surface inspection showing pattern and features

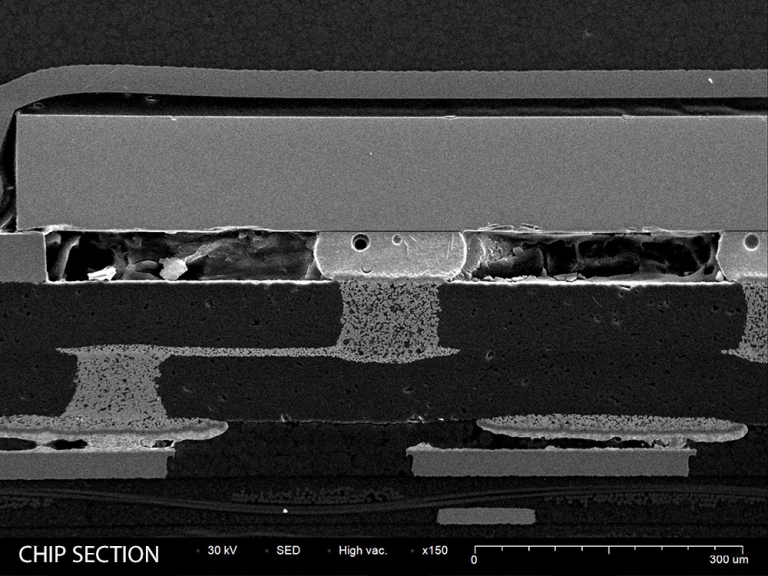

Chip Cross-Section

Integrated circuit cross-section showing layer structure

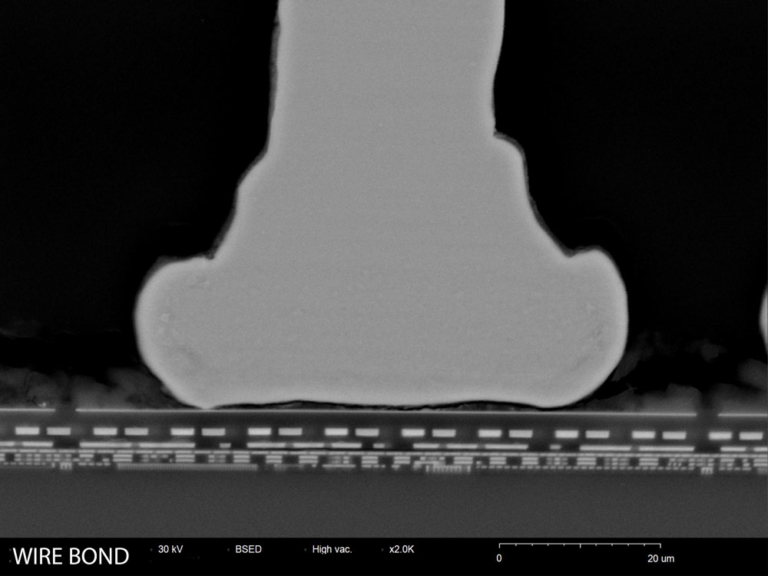

Wire Bonding

Gold wire bond connection to chip bond pad

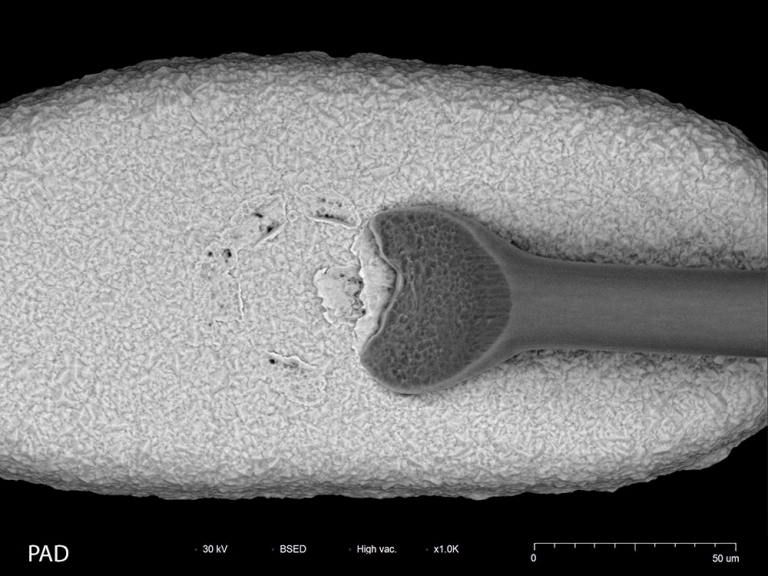

Bond Pad

Wire bond pad surface texture and interface

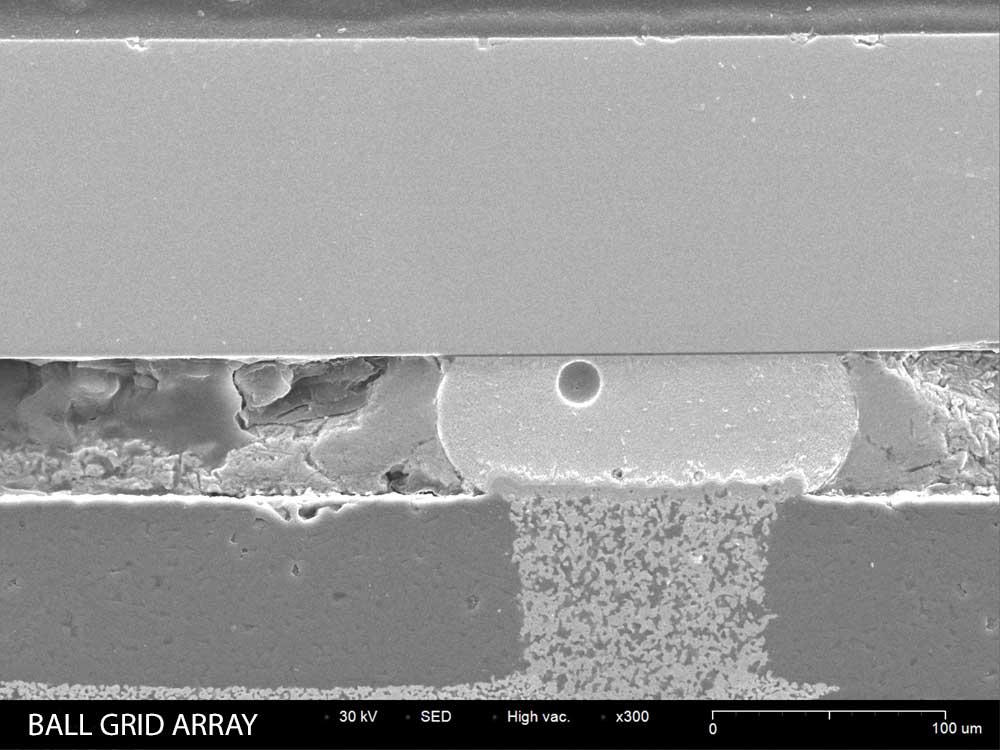

BGA Package

Ball grid array solder joint inspection

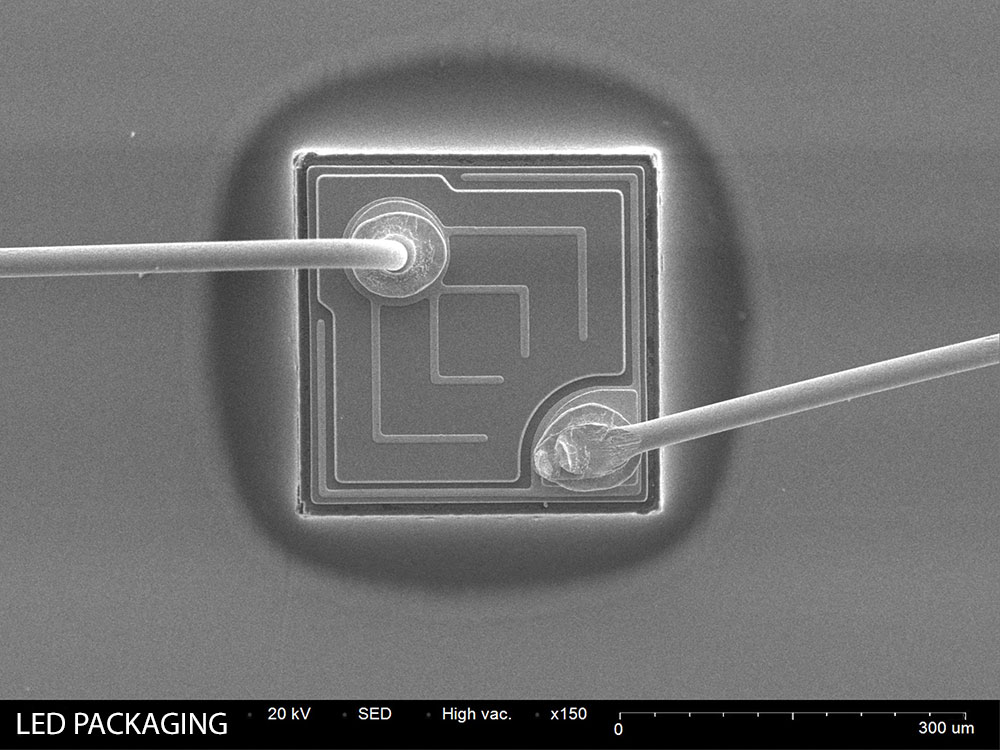

LED Packaging

LED die and wire bond assembly inspection

Recommended Analytical Techniques

SE Imaging

High-resolution topographic imaging for surface features, patterns, and structures.

BSE Imaging

Compositional contrast to distinguish materials and detect buried features.

EDS Analysis

Elemental identification of particles, contamination, and layer composition.

EBIC

Electron beam induced current for junction visualization and defect localization.

Recommended Equipment

SNE-Alpha Desktop SEM

Compact, high-resolution scanning electron microscope ideal for research and quality control applications.

Bruker XFlash EDS

Energy dispersive X-ray spectroscopy for elemental analysis and material identification.

MCM-100 Sputter Coater

Prepare non-conductive samples with gold or platinum coatings for optimal SEM imaging.

Related Applications

Resources

Explore Semiconductor Applications

See how the SNE-Alpha can support your semiconductor research and QC needs.

Request Sample Analysis