us

Materials Science

Comprehensive materials characterization for metals, polymers, composites, ceramics, and failure analysis

Materials science spans the study of all material classes—metals, polymers, ceramics, composites, and advanced materials. Scanning electron microscopy is the cornerstone analytical technique for understanding structure-property relationships, from microstructure to nanoscale features.

The SNE-Alpha desktop SEM delivers the resolution and analytical capabilities that materials scientists need without the footprint or complexity of floor-model systems. With 5nm resolution and integrated EDS capability, you can image surface morphology, analyze microstructure, and determine elemental composition all in one instrument.

Key Materials Science Applications

- Failure Analysis: Investigate fracture surfaces, corrosion, fatigue cracks, and manufacturing defects. BSE imaging reveals compositional variations while EDS identifies contaminants

- Microstructure Analysis: Characterize grain size, phase distribution, and crystallographic features. Essential for understanding mechanical properties and processing effects

- Coating and Surface Analysis: Measure coating thickness, evaluate adhesion, and inspect surface treatments. Cross-sectional imaging reveals layer structure

- Polymer Characterization: Examine polymer morphology, blend compatibility, filler distribution, and degradation mechanisms

- Composite Materials: Analyze fiber-matrix interfaces, void content, and damage mechanisms critical for aerospace and automotive applications

- Quality Control: Routine inspection of incoming materials, in-process components, and finished products for specification compliance

Material Classes

The SNE-Alpha handles the full range of materials:

- Metals and Alloys: Steels, aluminum, titanium, superalloys, and precious metals

- Polymers: Thermoplastics, thermosets, elastomers, and polymer blends

- Ceramics: Oxides, carbides, nitrides, and glass materials

- Composites: Carbon fiber, glass fiber, metal matrix, and ceramic matrix composites

- Coatings: Thermal barrier coatings, hard coatings, corrosion protection, and thin films

Materials Science SEM Images

Sample images captured with the SNE-Alpha desktop SEM.

Metal Microstructure

Secondary electron imaging showing surface topography

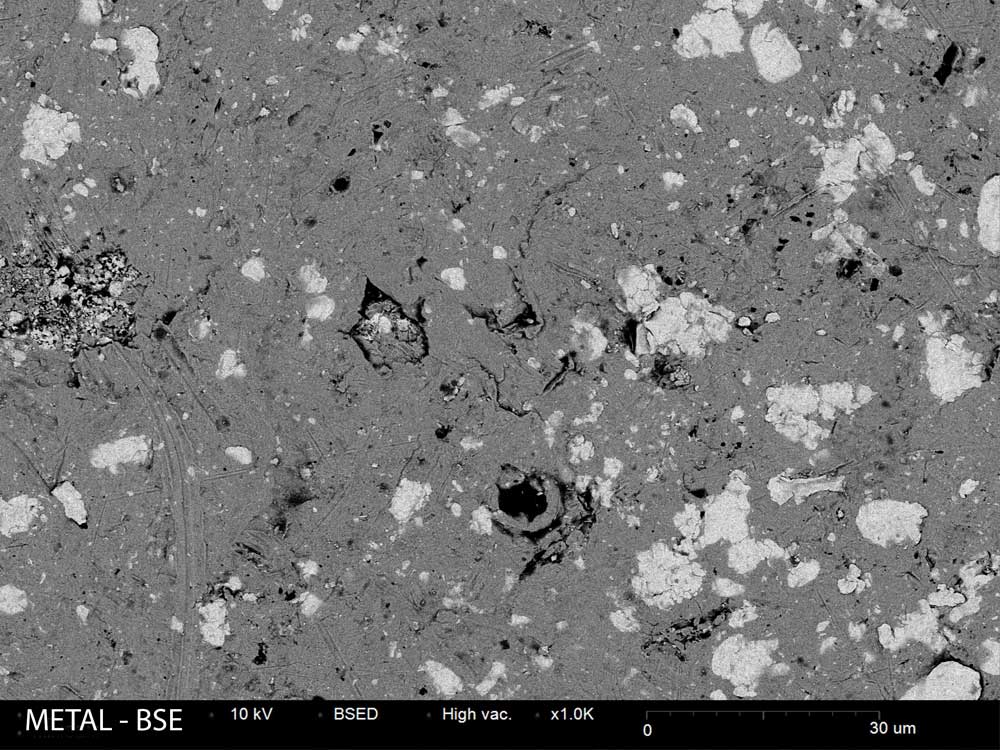

Compositional Contrast

Backscattered electron imaging revealing phase contrast

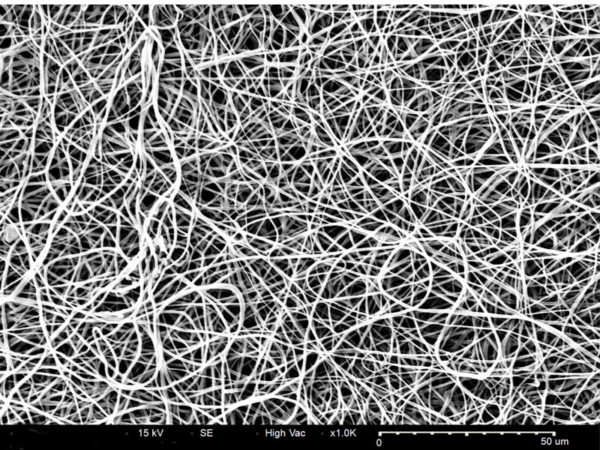

Fiber Composite

Fiber cross-section analysis for composite materials

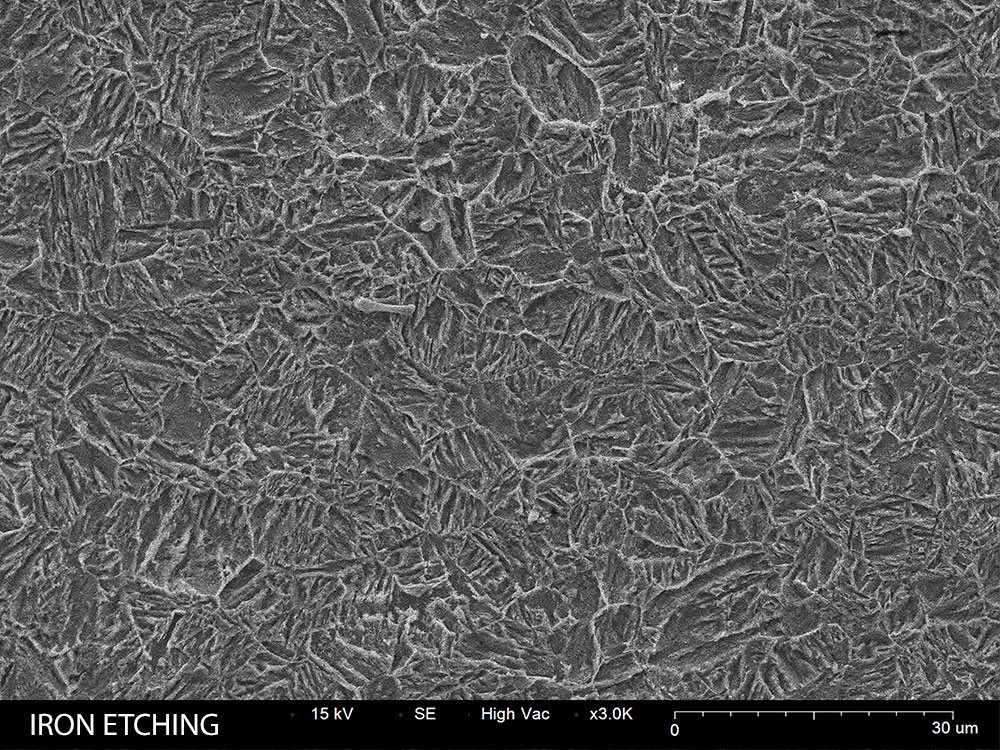

Etched Metal

Chemically etched surface showing grain structure

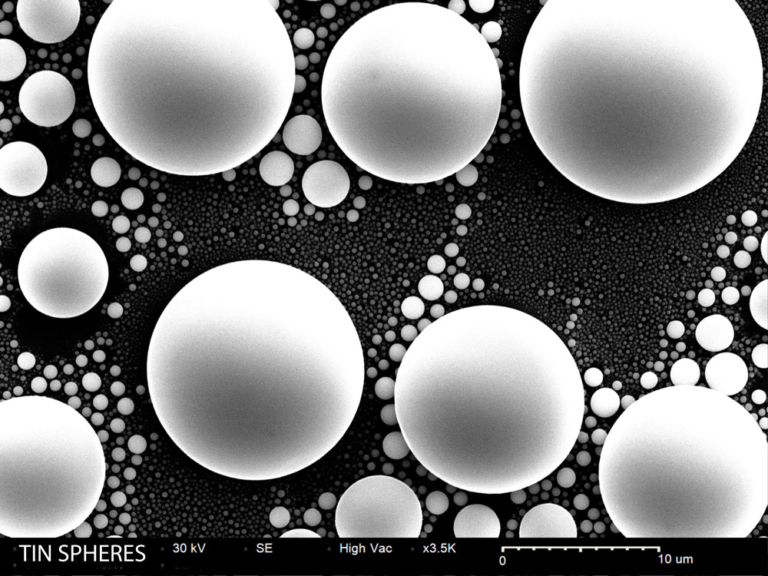

Metal Powder

Spherical powder for additive manufacturing

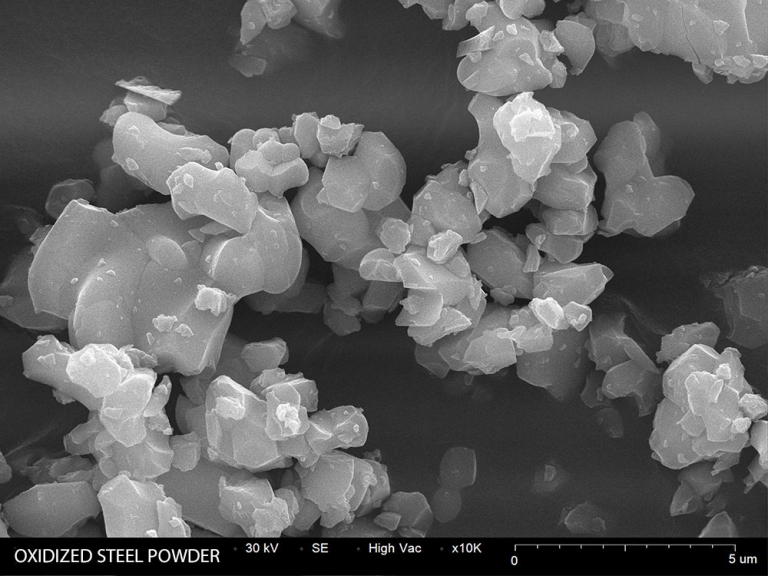

Steel Powder

Powder particle morphology and surface oxidation

Why Materials Scientists Choose the SNE-Alpha

5nm Resolution

Resolve fine microstructural features, nanoscale defects, and thin film structures with clarity.

Dual Detectors

SE for topography, BSE for composition. Switch instantly between imaging modes.

90-Second Vacuum

High sample throughput for production environments and QC laboratories.

EDS Integration

Add Bruker XFlash EDS for elemental analysis, phase identification, and composition mapping.

Large Chamber

Accommodate bulk samples up to 70mm diameter without extensive sectioning.

Simple Operation

Get results fast—intuitive software means no dedicated operator required.

Recommended Equipment

SNE-Alpha Desktop SEM

Compact, high-resolution scanning electron microscope ideal for research and quality control applications.

Bruker XFlash EDS

Energy dispersive X-ray spectroscopy for elemental analysis and material identification.

MCM-100 Sputter Coater

Prepare non-conductive samples with gold or platinum coatings for optimal SEM imaging.

Related Applications

Resources

Ready to See Your Materials in Detail?

Send us your samples and we’ll show you exactly what the SNE-Alpha can reveal.

Request Sample Analysis