Analytical Scanning Electron Microscopy (SEM): Principles, Techniques, and Considerations

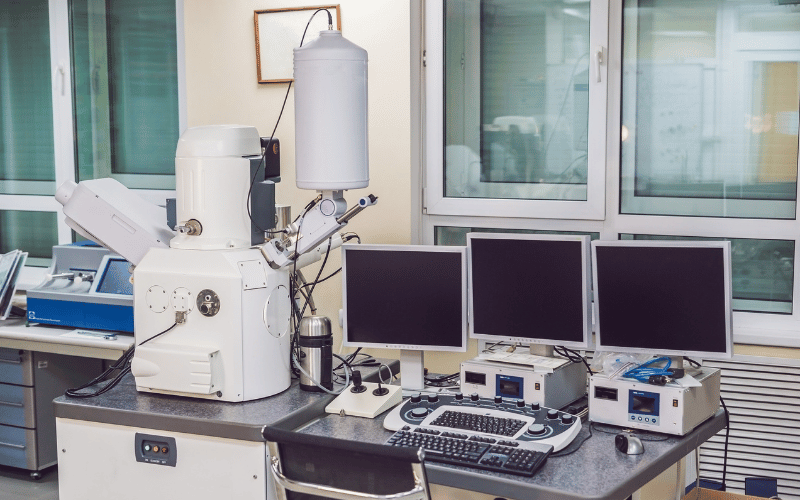

Scanning Electron Microscopy (SEM) is a go-to solution for high-resolution imaging and elemental analysis at the micro- and nanoscale. Analytical SEM extends the functionality of conventional SEM by integrating complementary techniques like Energy-Dispersive X-ray Spectroscopy (EDS) and Electron Backscatter Diffraction (EBSD), allowing researchers to obtain both morphological and compositional data from a wide range of samples.

Scanning Electron Microscopy (SEM) is a go-to solution for high-resolution imaging and elemental analysis at the micro- and nanoscale. Analytical SEM extends the functionality of conventional SEM by integrating complementary techniques like Energy-Dispersive X-ray Spectroscopy (EDS) and Electron Backscatter Diffraction (EBSD), allowing researchers to obtain both morphological and compositional data from a wide range of samples.

From semiconductor failure analysis to forensic investigations, analytical SEM has become a critical tool in both research and industry. Let’s explore some of its working principles, key components, imaging and analytical capabilities, and considerations for achieving high-quality results.

Fundamental Principles of Analytical SEM

Analytical SEM is based on the interaction between a high-energy electron beam and a sample surface. Electrons impinging on the surface generate various signals, including secondary electrons (SE), backscattered electrons (BSE), and characteristic X-rays, which can be collected and analyzed. These interactions allow researchers to study both the surface structure and elemental composition of materials with nanometer-scale resolution.

Primary Electron Beam Interaction

The core of SEM operation relies on a focused electron beam that is scanned over the sample surface, producing:

- Secondary Electrons (SE): These low-energy electrons originate from the sample surface and provide high-resolution topographic images. Surface roughness, material composition, and beam energy influence the contrast in SE images.

- Backscattered Electrons (BSE): These high-energy electrons are scattered back from deeper within the sample. Because their intensity depends on atomic number (Z), BSE imaging is useful for compositional contrast, with heavier elements appearing brighter.

- X-ray Emission (EDS Analysis): The interaction between the electron beam and sample atoms results in the emission of characteristic X-rays, which provide elemental information. EDS spectra can be used to quantify element concentrations and map their distribution across a sample.

Additional signals, such as cathodoluminescence (CL) and Auger electrons, can provide further insight into a material's electronic and chemical properties, expanding the scope of SEM analysis.

Key Components of Analytical SEM

1. Electron Source (Gun)

The electron source determines beam brightness, energy spread, and resolution. Common types include:

- Tungsten Filament: A cost-effective option with moderate resolution and beam stability.

- Lanthanum Hexaboride (LaB₆): Offers higher brightness and a longer lifespan than tungsten.

- Field Emission Gun (FEG): Provides extremely high resolution due to its small probe size and high beam coherence, making it ideal for nanoscale analysis.

2. Electromagnetic Lenses and Beam Control

Electromagnetic lenses focus and control the electron beam. Two key components are:

- Condenser Lenses: Regulate beam current and spot size, affecting image resolution and analytical sensitivity.

- Objective Lens: Final focusing lens that determines working distance, depth of field, and resolution.

3. Sample Chamber and Stage

The SEM sample chamber must maintain a high vacuum to prevent electron scattering. Specialized sample stages allow for:

- Tilting and Rotation: Facilitates crystallographic analysis using EBSD.

- Cooling or Heating: Environmental SEM (ESEM) enables imaging of hydrated and biological samples.

- Large Area Mapping: Motorized stages provide precise, automated imaging over wide sample areas.

4. Detectors for Image Acquisition

- Secondary Electron Detector (SEI): Produces high-resolution images of surface morphology.

- Backscattered Electron Detector (BSD): Provides compositional contrast based on atomic number variations.

- X-ray Detectors: Capture emitted X-rays for elemental analysis and mapping.

- Wavelength Dispersive Spectroscopy (WDS): Offers higher spectral resolution than EDS, particularly useful for resolving overlapping X-ray peaks.

Analytical Capabilities of SEM

1. Imaging Performance

Analytical SEM achieves spatial resolutions down to a few nanometers, with field-emission SEMs (FE-SEMs) providing the highest resolution. Factors affecting image quality include:

- Accelerating Voltage: Higher voltages increase penetration depth, improving imaging of bulk materials but reducing surface sensitivity.

- Spot Size: A smaller probe size enhances resolution but may reduce signal intensity.

- Working Distance: Shorter distances improve resolution but may limit depth of field.

2. Elemental Analysis via EDS

Energy-Dispersive X-ray Spectroscopy (EDS) detects characteristic X-rays emitted from elements in a sample. Key considerations include:

- Quantitative Accuracy: EDS quantification requires corrections for matrix effects, absorption, and fluorescence.

- Spatial Resolution: Limited by electron beam interaction volume (typically 1–3 µm at 15 kV).

- Detection Limits: Generally in the 0.1–1 wt% range, with lighter elements (e.g., Be, B, C) more challenging to detect.

3. Crystallographic Analysis via EBSD

Electron Backscatter Diffraction (EBSD) provides information on grain orientation, phase distribution, and strain within crystalline materials. It is particularly useful in metallurgy and geological sciences.

4. Complementary Techniques

- Cathodoluminescence: Examines defects and electronic structure in semiconductors.

- X-ray Photoelectron Spectroscopy (XPS): Analyzes surface chemistry and oxidation states.

- Focused Ion Beam (FIB-SEM): Enables site-specific sample preparation for TEM and cross-sectional analysis.

Considerations for Optimal SEM Performance

Sample Preparation

Non-conductive samples need special treatment before imaging. Sputter-coating with gold (Au), platinum (Pt), or carbon (C) is essential to prevent charging effects. For hydrated biological samples, cryo-SEM techniques help preserve their natural state, avoiding dehydration and structural changes.

Beam-Sample Interaction Control

Adjusting the electron beam voltage can optimize imaging outcomes. Lower voltages enhance surface sensitivity, revealing fine details on the sample’s exterior. In contrast, higher voltages provide deeper penetration for bulk analysis. When working with insulating samples, Variable Pressure SEM (VP-SEM) offers a solution by enabling imaging without requiring a conductive coating.

Spectral Overlaps in EDS

EDS sometimes encounters challenges with spectral overlaps, especially when analyzing high-atomic-number (Z) elements. In such cases, wavelength-dispersive spectroscopy (WDS) can offer superior peak separation, leading to more precise elemental identification.

Avoiding Artifacts

Several factors can compromise image quality in SEM analysis. Beam damage may alter sample morphology, contamination can introduce misleading features, and charging effects can obscure details. To mitigate these issues, employing complementary techniques can provide a more comprehensive understanding of the sample’s properties. Raman spectroscopy with SEM, for instance, is particularly useful for identifying chemical composition and detecting structural changes without altering the sample.

Closing Thoughts

Analytical SEM is a powerful tool that provides critical insights into the structure, composition, and properties of materials. By combining high-resolution imaging with elemental and crystallographic analysis, SEM plays a crucial role in fields ranging from semiconductor manufacturing to forensic science. Understanding its principles, capabilities, and limitations is essential for optimizing its use in research and industry.

Contact a member of the Nano Images team to learn more about integrating high-resolution imaging with complementary detection methodologies. Whether you're tackling semiconductor defect analysis, forensic investigations, or breakthrough nanotechnology research, our innovative SEM systems deliver results with efficiency and accuracy. Discover how we can elevate your analytical capabilities—schedule a demo today.