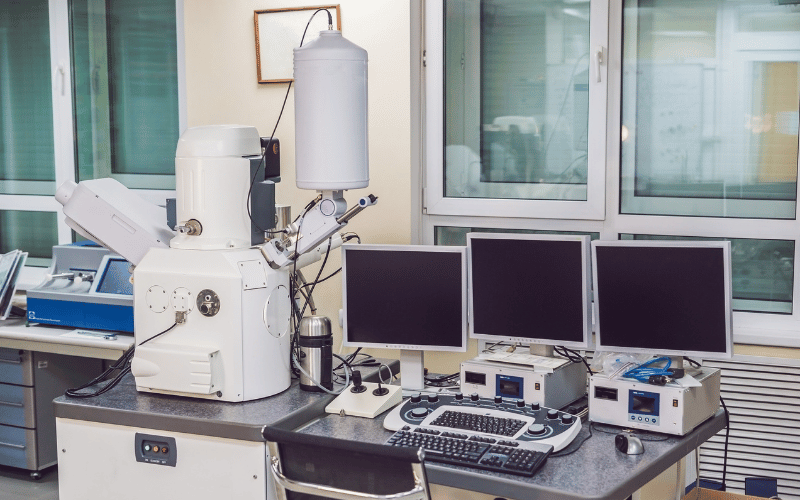

Preventive Maintenance for Your Scanning Electron Microscope

When conducting scientific research, your Scanning Electron Microscope (SEM) is a crucial tool for obtaining accurate and detailed results across various applications. To ensure its reliability and optimal performance, proactive measures like preventive maintenance for SEMs are paramount. Let’s discuss why regular maintenance is essential and how partnering with the right service provider can safeguard your investment.

Why Perform Preventive Maintenance?

Preventive maintenance goes beyond just fixing issues as they arise. It involves all efforts to address potential problems preemptively. This proactive approach aims to keep your SEM in top-notch condition by ensuring cleanliness, proper functioning of all parts, and anticipating any potential breakdowns. Also, working with a customer-centric service provider is a must. Look for one that emphasizes the importance of preventive maintenance in reducing downtime and maintaining the efficiency of your laboratory processes.

The Significance of Preventive Maintenance

Like any other machine, SEMs require care to perform as expected. Regular SEM maintenance is similar to changing the oil in your car – neglecting it can lead to breakdowns and compromised performance. Here are the reasons why maintenance and routine servicing is important:

Minimizing Unexpected Failures

Proactively identifying and resolving potential issues before they escalate acts as a preventive shield against significant disruptions. Regular maintenance ensures that your SEM is always ready when you need it the most.

Maintaining Calibrations

Key calibrations within the SEM are pivotal for accurate and reliable results. Routine maintenance ensures that these calibrations are upheld, safeguarding the integrity of your research outcomes.

Ensuring Superior Image Quality

The heart of detailed analysis and research lies in the quality of images produced by your SEM. Regular maintenance contributes significantly to sustaining superior image quality, a fundamental aspect of your scientific work.

Performing SEM Maintenance and Repair

When performing regular SEM maintenance and repair, you should seek help from industry professionals. A reliable partner offers services tailored to your needs, including the following:

Full Coverage Service Plan

For SEMs equipped with advanced technologies, a comprehensive plan covers all aspects, including parts, labor, travel expenses, and, of course, preventive maintenance. This ensures your SEM operates at its optimal capacity, providing reliability and peace of mind.

Per Diem Servicing

When your SEM requires repair, on-demand services tailored to its unique needs become indispensable. This service package not only addresses specific issues but also includes preventive maintenance measures. Skilled engineers are readily available to ensure swift problem resolution.

Preventive Maintenance

Beyond mere problem-solving, preventive maintenance involves a proactive partnership with service providers. This collaborative effort anticipates potential issues, ensuring the cleanliness and proper functioning of all SEM components. Partnering with a customer-centric company underscores the significance of this preventive approach, allowing you to enjoy reduced downtime and sustained laboratory efficiency.

The following tasks collectively contribute to the seamless operation of your equipment:

System Evaluation

A thorough assessment of the entire SEM system, including add-on accessories, guarantees that every component functions at its best.

Column Cleaning

Ensuring the cleanliness of the SEM column is crucial for optimal performance. This task is vital in preventing issues and preserving image quality.

Calibration

Precise calibration of magnification and other settings is a critical step to guarantee the accuracy and consistency of the SEM results.

Parts Replacement

Timely replacement of components such as filaments, apertures, and scintillators is essential for preventing unexpected failures and ensuring the longevity of your SEM.

Diligently performing these tasks not only addresses potential issues before they escalate but also contributes to the overall reliability and longevity of your equipment. A well-maintained SEM translates to consistent, high-quality results in your research and analysis efforts.

Key Takeaways

Performing regular preventive maintenance and choosing the right service company is crucial for the well-being of your SEM.

Don’t wait for issues to arise; be proactive in safeguarding your equipment assets. Always work with a company offering preventive maintenance services to optimize your SEM’s performance, reduce downtime, and ensure seamless research and analysis processes. Your SEM deserves the best care for consistent, top-quality results.