Metallurgy

Metal microstructure, grain analysis, heat treatment effects, and failure investigation

Metallurgical analysis requires detailed examination of microstructure at scales beyond optical microscopy. Scanning electron microscopy provides the resolution and depth of field needed to characterize grain structure, phase distributions, precipitates, and fracture surfaces in metals and alloys.

The SNE-Alpha desktop SEM delivers metallography-grade imaging in a compact format suited for quality control labs, machine shops, and educational metallurgy programs. Combined with EDS, it enables both structural and compositional analysis of metallic materials.

Key Metallurgy Applications

- Microstructure Analysis: Examine grain size, shape, and distribution. Identify phases, inclusions, and precipitates in polished and etched samples

- Fracture Analysis: Characterize fracture surfaces to determine failure mode—ductile, brittle, fatigue, or stress corrosion

- Heat Treatment Verification: Assess effectiveness of heat treatment by examining resulting microstructure and phase distributions

- Weld Inspection: Examine weld zones, heat-affected zones, and base metal to assess weld quality and identify defects

- Coating Analysis: Measure coating thickness, examine adhesion, and identify coating composition

- Corrosion Studies: Characterize corrosion products, pit morphology, and attack patterns

Sample Preparation

Standard metallographic preparation produces excellent results for SEM analysis:

- Mounting: Conductive mounting compounds eliminate charging; carbon-filled epoxy is recommended

- Grinding & Polishing: Standard metallographic preparation to 1µm or better

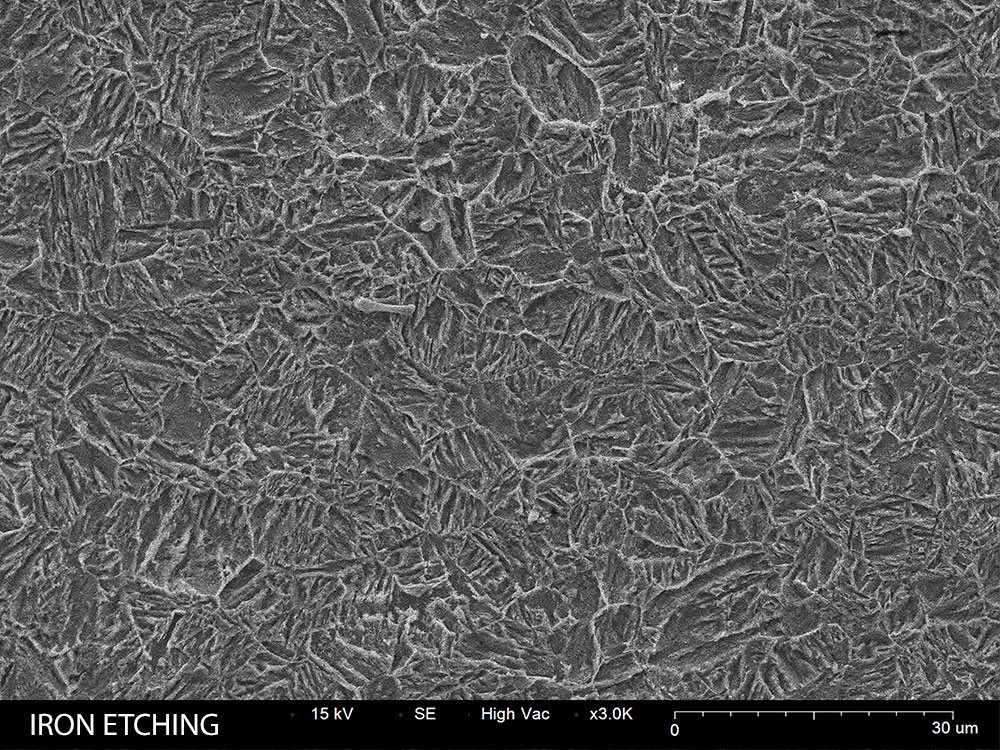

- Etching: Chemical etching reveals grain boundaries and phase contrast for SE imaging

- As-polished: Unetched samples work well for BSE imaging and EDS analysis

Metallurgy SEM Images

Sample images captured with the SNE-Alpha desktop SEM.

Metal Surface (SE)

Secondary electron imaging showing surface topography

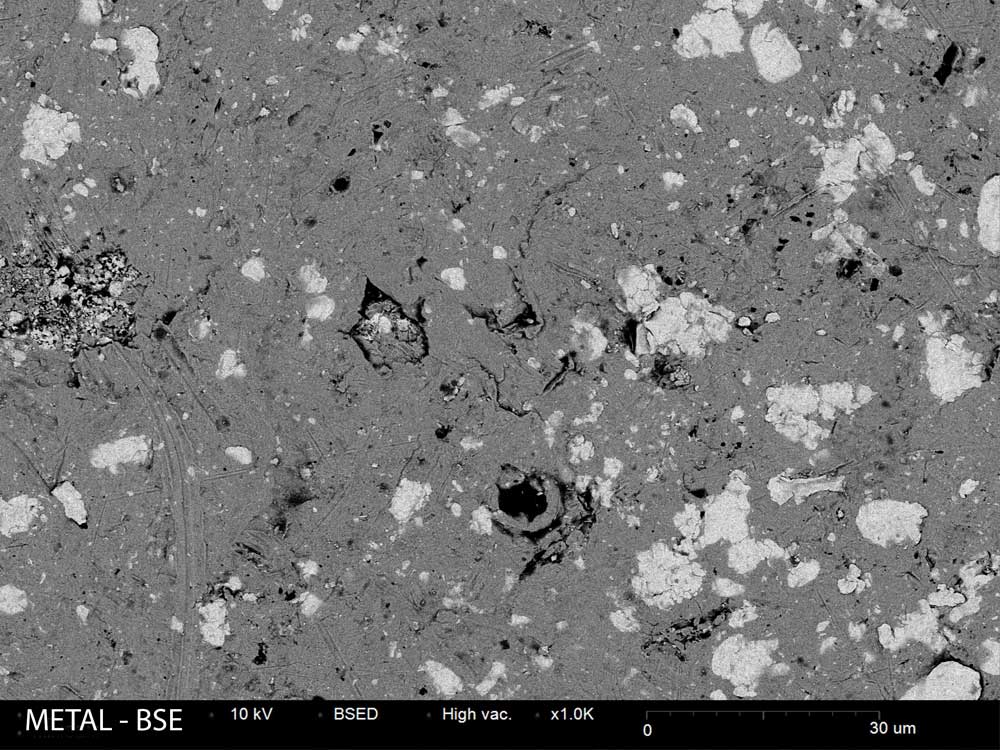

Metal Microstructure (BSE)

Backscattered electron imaging revealing phase contrast

Etched Iron

Chemically etched iron showing grain structure

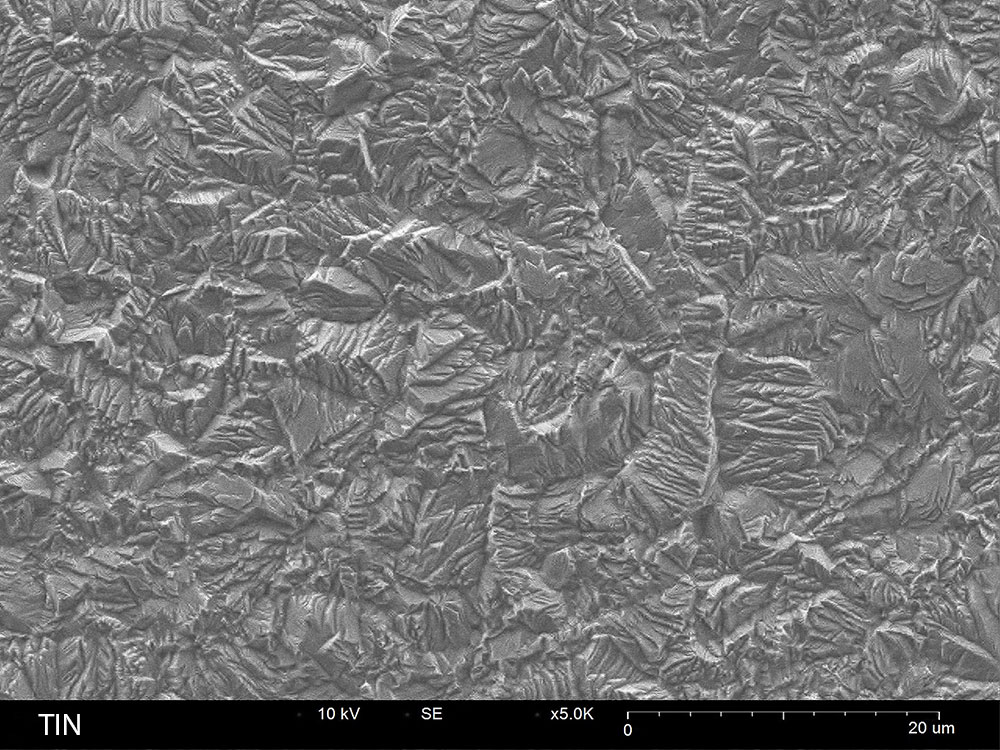

Tin

Tin metal surface morphology and crystal structure

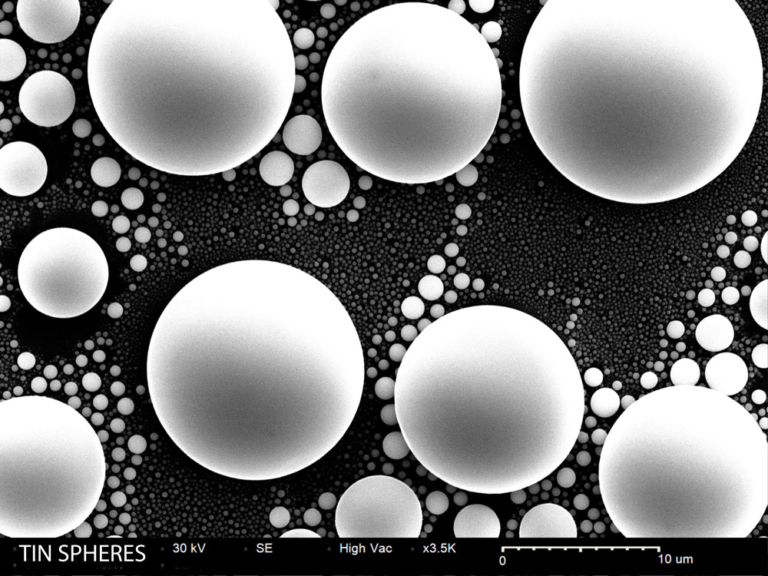

Tin Spheres

Spherical tin particles at high magnification

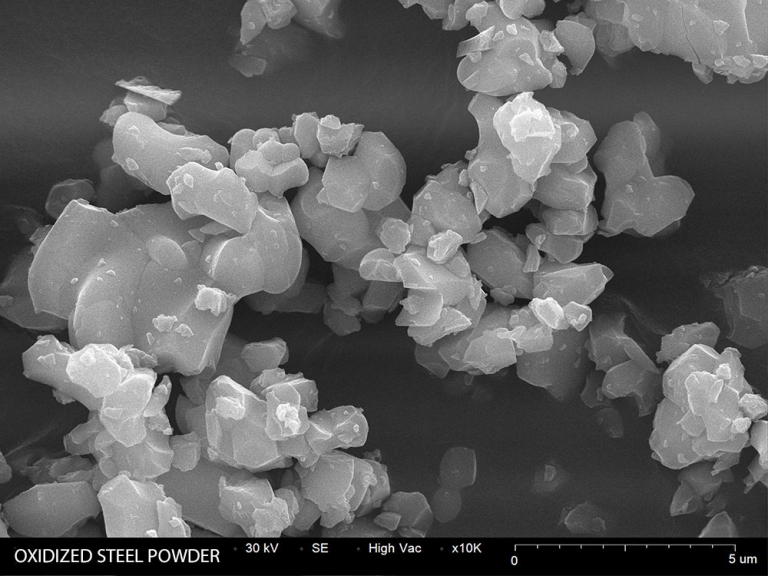

Oxidized Steel Powder

Steel powder particles showing oxidation layer

Analytical Techniques

SE Imaging

Topographic imaging of etched samples reveals grain structure, phase morphology, and surface features.

BSE Imaging

Compositional contrast distinguishes phases by atomic number on polished, unetched samples.

EDS Analysis

Identify phases, inclusions, and precipitates by elemental composition. Verify alloy composition.

EDS Mapping

Visualize element distribution across welds, coatings, and diffusion couples.

Recommended Equipment

SNE-Alpha Desktop SEM

Compact, high-resolution scanning electron microscope ideal for research and quality control applications.

Bruker XFlash EDS

Energy dispersive X-ray spectroscopy for elemental analysis and material identification.

MCM-100 Sputter Coater

Prepare non-conductive samples with gold or platinum coatings for optimal SEM imaging.

Related Applications

Resources

Metallurgical Analysis Solutions

See how the SNE-Alpha can support your metallurgy lab and quality control needs.

Request Sample Analysis