Transportation

Automotive materials, wear analysis, component inspection, and failure investigation

The transportation industry relies on materials that must withstand demanding conditions—high temperatures, friction, corrosion, and cyclic loading. Scanning electron microscopy provides the detailed analysis needed to develop materials, investigate failures, and ensure component reliability across automotive, rail, marine, and heavy equipment applications.

The SNE-Alpha desktop SEM enables transportation engineers and quality teams to perform materials characterization in-house. Combined with EDS for elemental analysis, it supports everything from routine quality control to complex failure investigations.

Key Transportation Applications

- Brake System Analysis: Examine friction material morphology, wear mechanisms, and transfer film formation on brake pads and rotors

- Engine Components: Characterize cylinder bore surfaces, piston ring wear, and valve seat deposits

- Bearing Analysis: Investigate wear patterns, surface damage, and lubricant contamination in rolling element and journal bearings

- Coating Evaluation: Assess thermal barrier coatings, hard chrome, and other protective surface treatments

- Fuel System Components: Analyze injector nozzle wear, filter media, and fuel system deposits

- Tire and Rubber: Examine rubber compound structure, reinforcement dispersion, and wear patterns

Failure Analysis Applications

SEM provides critical evidence for transportation failure investigations:

- Fracture Analysis: Examine fracture surfaces to determine failure mode—fatigue, overload, brittle fracture, or stress corrosion

- Wear Mechanism Identification: Distinguish between adhesive, abrasive, erosive, and corrosive wear

- Contamination Analysis: Identify foreign materials and contamination sources using EDS

- Manufacturing Defects: Detect porosity, inclusions, and processing defects in cast and machined components

Transportation SEM Images

Sample images captured with the SNE-Alpha desktop SEM.

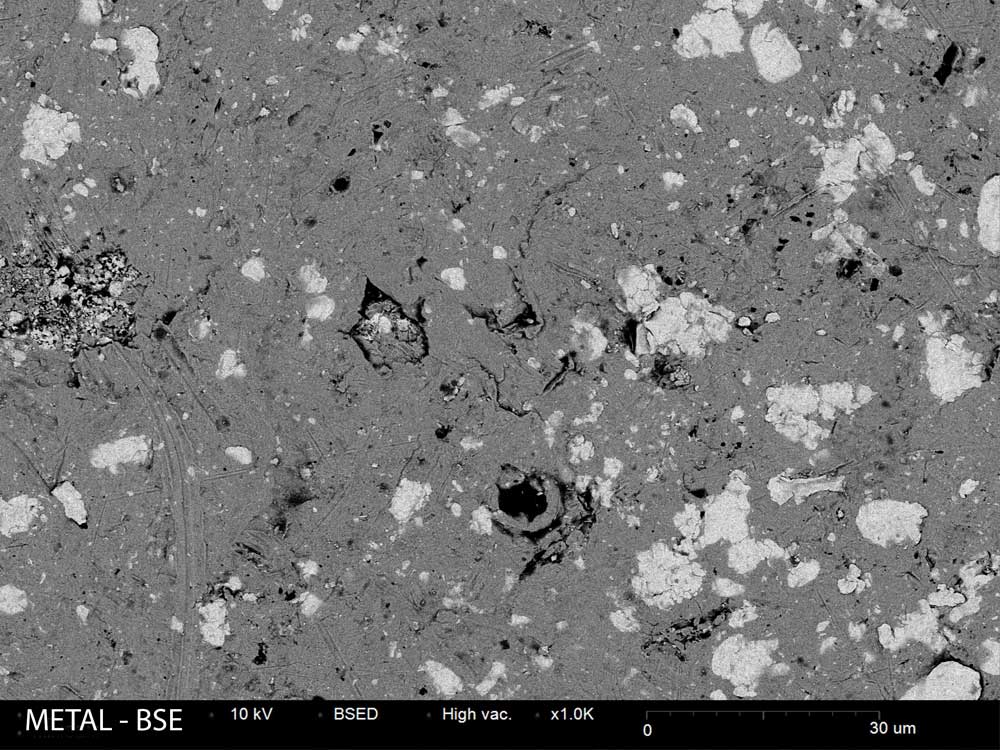

Metal Surface

Engine component surface morphology analysis

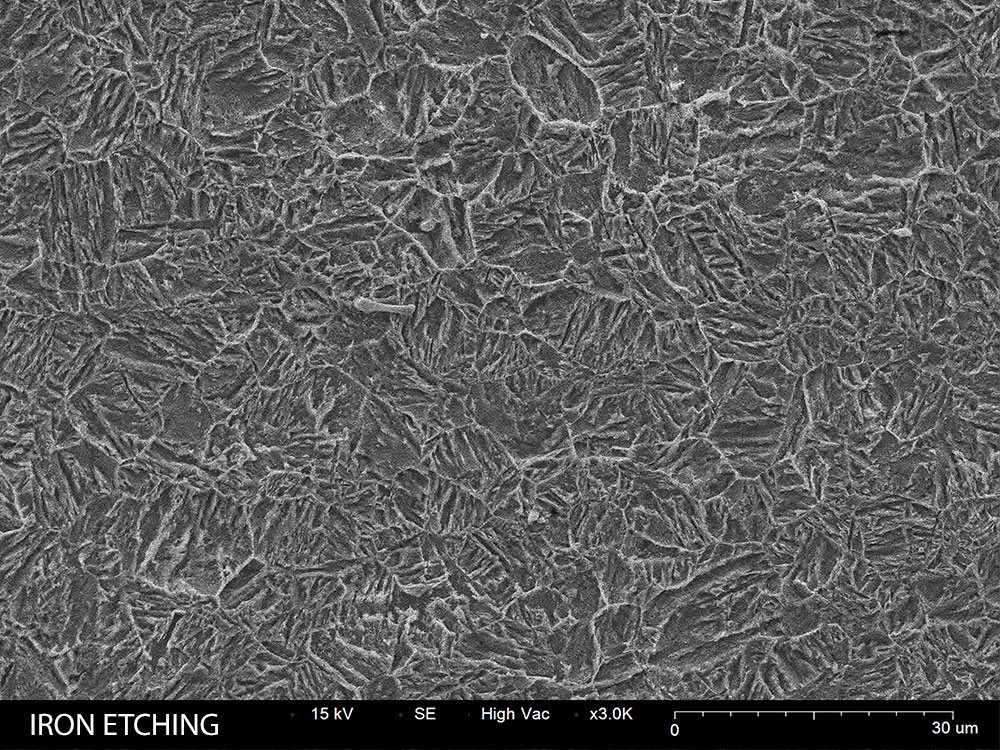

Metal Microstructure

Etched surface revealing grain boundaries

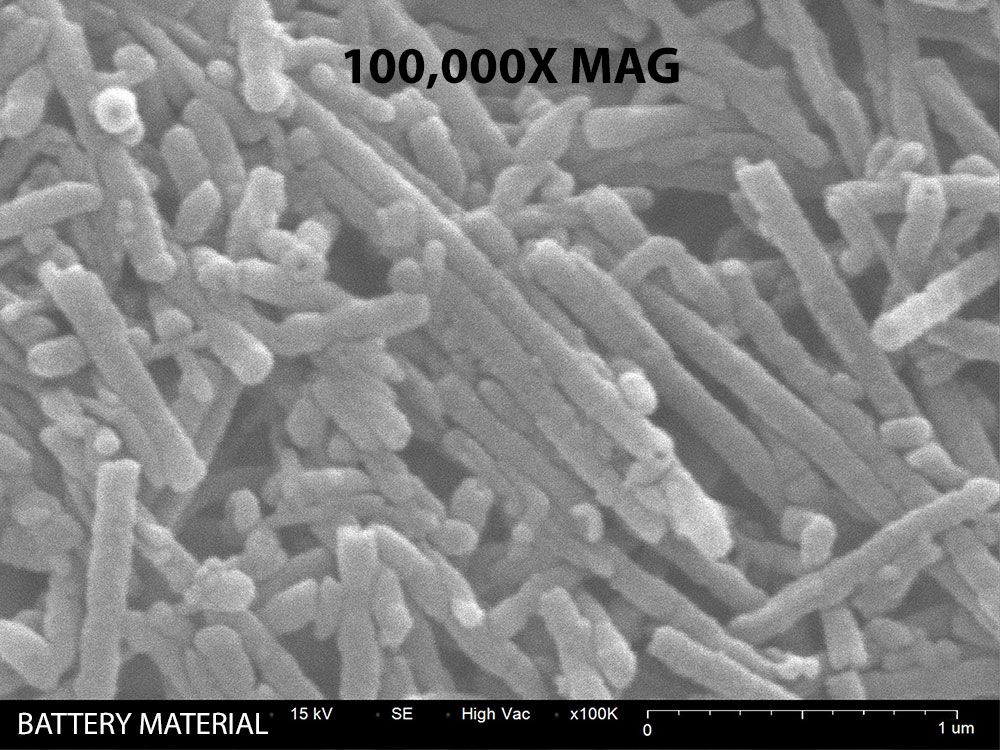

EV Battery Material

Electric vehicle battery electrode characterization

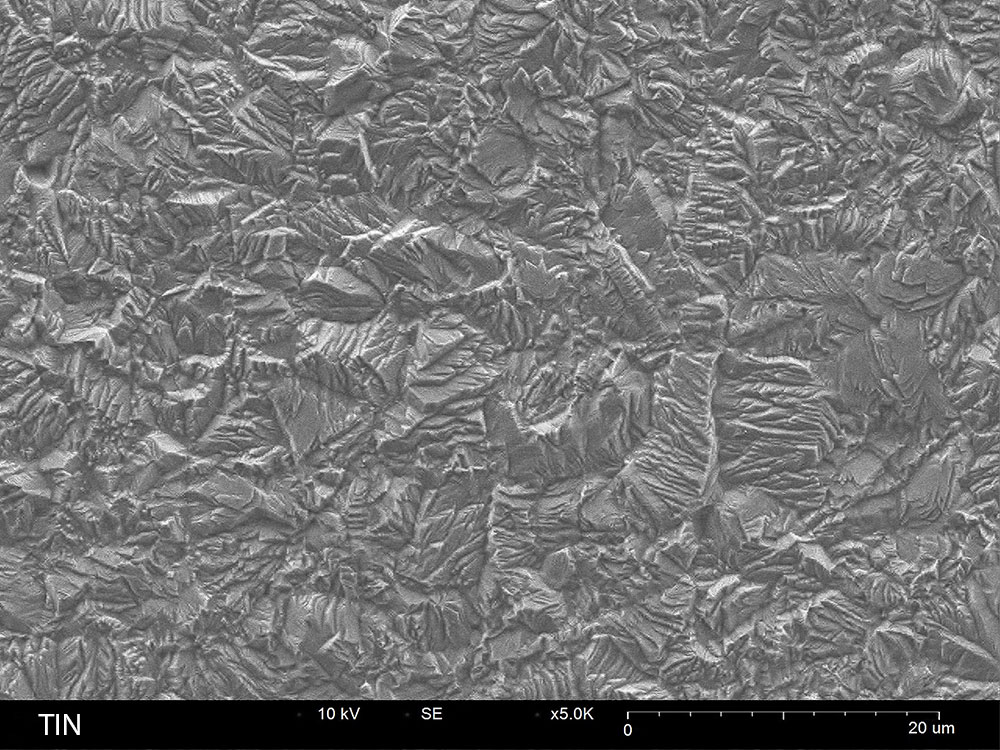

Bearing Material

Tin-based bearing alloy microstructure

Component Analysis

Backscatter imaging for compositional analysis

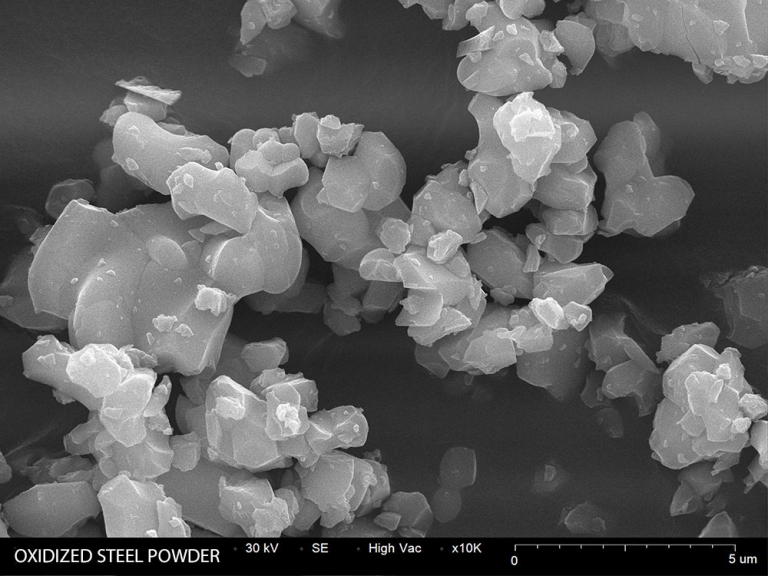

Metal Powder

Powder metallurgy materials for automotive parts

Industry Applications

Automotive OEM

Support materials development, quality control, and warranty analysis for automotive manufacturers.

Tier Suppliers

Characterize component materials and verify specifications for brake, bearing, and drivetrain suppliers.

Heavy Equipment

Analyze wear-resistant materials and failure mechanisms in construction and mining equipment.

Fleet Maintenance

Investigate premature failures and optimize maintenance intervals with wear debris analysis.

Recommended Equipment

SNE-Alpha Desktop SEM

Compact, high-resolution scanning electron microscope ideal for research and quality control applications.

Bruker XFlash EDS

Energy dispersive X-ray spectroscopy for elemental analysis and material identification.

MCM-100 Sputter Coater

Prepare non-conductive samples with gold or platinum coatings for optimal SEM imaging.

Related Applications

Resources

Transportation Materials Analysis

See how the SNE-Alpha can support your automotive and transportation materials programs.

Request Sample Analysis